It shouldn't surprise you to hear that, as a standard-issue LEGO fan, I felt quite an inherent resistance against LEGO clones for most of my bricky journey. And I can comfortably say that for the large share of that period, that resistance was well founded: those clones were regularly of such low quality in so many respects, that trying to deal with them felt like a grotesque travesty of what proper LEGO experience should actually be like.

But, throughout several recent years, the scene began subtly changing its shape. Yes, there were (and still are) truckloads of inexcusably horrible cloning companies, blatantly ripping off official sets and community's ideas, and those are the manufacturers I truly don't want to have anything with. But interestingly, a small but significant number of exceptions floated to the surface. Exceptions which did not hide their LEGO-based fundamentals, but at least showed intention to do things properly, to the extent possible. And one of them is CaDA, whose Italian Supercar set received some unexpectedly strong praise. Sufficient praise, mind you, for me to cautiously order it.

Honestly, I had no idea whatsoever what to expect: this is among the most expensive clone sets one can find in the market overall, yet compared to its functions and a staggering number of parts, nevertheless it seemed almost suspiciously cheap. The only sensible reference for comparison I could put it against were LEGO's own contenders in the field, id est, its Technic supercars of comparable shape, complexity and role (among which I was lucky enough to have the heavyweight Bugatti Chiron at hand).

And so on one rainy Friday, CaDA's package arrived at my door, inconspicuously hidden in a plain beige box.

No love at no first sight

Now, it would be easy to just dive into a "classic" overly comprehensive review which enumerates every single trifle in great length, but that would be completely pointless. Not only because there already are many such police-investigation-type reviews out there, but because I want to focus on the actual experience of this set, and not on the finnicky technicalities that tend to get in the way of essentials.

Sparkling with curiosity, I opened the huge box with a nice motif of the car's bodywork, and was facing a group of smaller boxes, all densely packed with parts, fitting snugly together in a neat slanted pattern. This is nothing new; indeed, LEGO does the same for its flagship sets. But for a clone, this is unusually sophisticated, thought I to myself.

So, we've got enumerated boxes with, furthermore, enumerated transparent bags inside, all refering to major building steps in the six instruction booklets. Sounds familiar? It should, because this is how LEGO's sets have been organized for quite some time already ― and to that extent, I should say, following its successful recipe makes sense. All that remains is finding a suitably large building surface, and we're ready to rock.

History, branding... and the lack of them

Before proceeding to the set itself, a word about its background story. For this project, CaDA hired Bruno Jenson as the designer. If you have been diligently navigating the Technic community waters, the name should have a familiar ring: that's no other than Brunojj1, the well-known member of the Technic community, renowned for his widely acclaimed Technic cars. Consulting one of such distinguished masters totally makes sense if you're trying to make an impact in the Technic (or rather, Technic-like) world right away. And Bruno's authorship is not hidden in any way ― to the contrary, his signature is prominently featured in many places around the box, instructions and elsewhere.

As for the model, in everything but its name, this is clearly a Ferrari 488 Pista, the 720-horsepower Italian beast. Official Ferrari branding, even if it were possible (because LEGO may have an exclusive contract in place), would probably add a hefty chunk of price to it, just in return for some prancing horse stickers ― therefore, the decision to omit it was to be expected here. On the other hand, LEGO would probably have no choice but to cringe and license their model, since selling an obvious replica would cause them more harm than good.

The choice of a 488 among several Ferraris is an interesting one. It may be down to someone's personal taste, to its difficult bodywork to model (though ― any Ferrari would be difficult), or to something else entirely.

Tremble to assemble

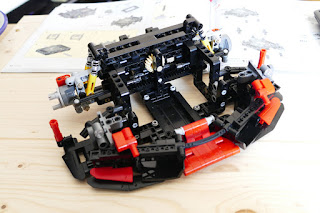

So, back to our crafting table ― and several striking facts surface immediately, before even finishing the first instruction booklet.

As you are probably aware, LEGO follow certain coloring rules when dealing with the elementary Technic parts, especially connectors. For example, 3L friction pins are usually blue, frictionless axle pins beige, and 2L axles red. The rationale is well known: it makes the parts easier to find while building, and also easier to sort during disassembly.

To put it short, CaDA does not, and it relies on black almost exclusively, thus producing two effects: disassembly of this set will definitely be a headache, but on the other hand, the set looks neat and consistent ― both its bodywork and interior.

Furthermore, while the "sea of black" may look tidy, it makes the assembly a bit harder, as it may be occasionally difficult to get proper bearings when trying to find your way around a million black items in the instruction booklet. But more on that later.

Another observation is that CaDA does not shy away from very advanced building techniques, which occasionally cross slightly into the territory considered illegal by LEGO. Mind you, they are still perfectly valid and widely used among the community builders, but as we know, LEGO go to great lengths to avoid even the slightest part tensions. Here, concepts like a half-inserted friction pin or a stud inserted into the axle hole are simply and pragmatically accepted ― whether you like it or not.

Mastery of design

And soon it becomes apparent, and stays so for the remainder of this building adventure, how insanely designed this car actually is. I'd go as far to claim that ― in the world of LEGO and its clones' sets ― this is easily the most sophisticated mechanical design I've ever encountered. The designer went to great lengths, accepting the cost of increased construction complexity, to follow many subtle curvy shapes of the original Ferrari perfectly. The amount of modeling skill and care invested into the bodywork is just tremendous.

And for the most part, its underlying chassis is strong and clever enough to keep the bodywork sufficiently rigid to easily survive usual driving and play. As many of us have learned, reaching either the trueness of design or the construction strength alone may be difficult at times, but is within the grasp of most builders. However, hitting both targets in the same model, like this Ferrari does, requires some impressive skills, as well as lots of patience. The cabin interior is just as impressively detailed, and contrary to many examples, it is free from various cables, axles, or other stuff.

Yet once we dive from the bodywork deep into the mechanics, the story just keeps becoming crazier.

So just to give you a clear picture, what the designer managed to squeeze underneath that glorious 1:8 bodywork are: remote steering, a remotely controlled sequential 4-speed gearbox with working steering wheel paddles, full independent double wishbone suspension, a V8 engine, remotely controlled lights, openable engine cover and doors with working handles, and a remotely powered drive.

Yes, while you're getting up from the floor, you did read that correctly: there are two servo motors (for steering and the gearbox), and two PF L-equivalent motors for drive, along with the lithium battery powering all of that, somehow crammed in the car along with all those other mechanical features. Density of features is breathtaking, even if you are otherwise familiar with top community builders' work.

The gearbox alone deserves an article on its own, such is the engineering prowess displayed here. It takes quite some concentration to grasp its functioning, featuring two synchronized gear changers that produce four trasmission ratios. We have already seen gearboxes with more speeds, but a sequential one powered by a servo motor, of this compact size yet considerable strength, breaks the ice.

It's not only about the gearbox, however. At many steps in the entire building process, I found myself wondering at how something is supposed to work, only to have an "aha! How clever" moment few minutes later.

Blood, Sweat and Tears

As one would expect, all this sophisty doesn't come for free. Quite simply said, this is a difficult set to build. Very difficult. And not only because of the experience and fine motor skills required to assemble some complex mechanisms and bodywork pieces, but even more because of the concentration which should be kept at maximum all the time.

Namely, it is very easy to make a mistake ― and at this level and density of features, any oversight will probably cost dearly later. This leads to what is, in my view, the main weakness of this set: its instructions. Only once you've tried the subperfect instructions can you appreciate the level at which LEGO do it.

I wouldn't say the instructions are downright bad ― after all, I managed to build the car ― but there is plenty of room for improvement to get to the standard LEGO level. For example, not all steps are perfectly clear; as a remedy, you can easily turn a few pages to find a suitable view later where some questionable part appears in its correct position, but the very need for that is an unnecessary complication, especially if there already is some space in the page for a proper "before & after" for the detail in question. And having so many black parts squeezed together does require an eagle eye to spot them. (Or preferably, two eagle eyes.)

Also, sometimes they progress from left to right, sometimes from top to bottom; due to monotonic colors of the innards, the chassis rotations are not always emphasized enough; and then there are pure errors: parts which are displayed in wrong positions, or are not there, or are there prematurely. Interestingly, instructions show the parts as they are manufactured by LEGO, rather than by CaDA: as if the instructions were created first, and the actual part design only completed later. This is in no way a problem for the actual building, but is a curiosity.

Bold mold

As for the quality of the parts themselves, the story is somewhat similar. These are, hands down, the best quality parts I've worked with among the LEGO clones, but at the same time, still trailing LEGO a bit.

It boils down to minute, precise tolerances. While the average force that holds e.g. an axle in an axle connector is roughly the similar to the one in LEGO, the variance here is noticeably wider. None was so bad that it would fall apart by itself, or that it could not be connected in the first place. But once you got used to LEGO's strict tolerances and consistent clutch forces, CaDA's seem a bit rough. Again, it does not affect the look or the end functionalities in any way, but affects the overall building impression.

Several reviewers have reported occasional miscast parts ― I haven't, but I cannot be sure whether I was just very lucky not to get any, or has CaDA improved its manufacturing process in the meantime.

There are also slight inconsistencies between the parts' color shades themselves: when observed next to each other, as they anyway end up in the finished model, even I with my poor color sight could discern slight differences between the various shades of reds. It's not a showstopper, especially if not under a strong light, but you may want to be aware of it should you plan to use this set as a showpiece. But then, to be fair, this is a criterion where LEGO's own performance has occasionally slipped in the recent years as well, so we can say CaDA is "down to standard".

Other than that, the parts are 100% compatible with LEGO, but are themselves not always identical. Especially not the beams, which have a distinct asymmetric pattern next to their axle holes: I'm not sure whether it makes the parts easier to manufacture, or cheaper, or more homogenous in the long run. It does not affect building in the least, but if you would like to mix these parts with your LEGO, you may want to be aware of that.

Sometimes, however, CaDA's different parts actually work better: its 36-tooth gear is actually superior to the LEGO's version, for example. Also, its trans-turquise brick separator with a special tool to extract friction pins is quite nice and useful. It's a matter of taste, but I'd also say the custom chrome rims work well ― as long as you pay attention not to leave any greasy fingerprints, that is. And the metal U-joints, fully optional because the familiar plastic ones are included as well, are the stars of the show.

The much-anticipated track day

So we've established that the design and engineering at work here is second to none, while the part and instruction quality is second only to LEGO. But how does this F488 fare as a remotely controlled toy car?

It's pretty agile despite its considerable size and weight, steers well, and the twin L-equivalent motors provide sufficient torque and power to move it around. The gear ratios don't differ as much as they do in real cars, so the actual chosen gear doesn't change the top speed that much, but you can still go for a thrill of starting in the 1st gear and then shifting upward as the car accelerates.

As the floor is rather low, you will have to make sure the driving surface is flat, and of course, any climbing is completely out of the question. If you're into that, better check out the current assortment of LEGO crawlers.

All the functions work very reliably, and the car itself is not prone to leaving a trail of lost parts behind itself. It's surprisingly sturdy ― in fact, once you learn where and how to hold it (that is, not by the roof), you will never worry about it disintegrating.

The wireless remote control controlling four independent channels on the lithium battery (drive, steering, gearbox and lights) in the car does its job fine and is not difficult to use. It is just an on-off control, without any progression in between, but you won't really miss that while driving.

To disassemble or not to disassemble

It's a hard choice, and I guess it will boil down to each individual, whether they consider themself primarily a collector or a builder. The set looks great on the shelf and being driven on the floor, but it is also a fantastic and abundant source of building material which would be very welcome to any Technic (or technicky) builder's assortment of raw materials. If your pockets are painfully deep, just go ahead and buy two: have one on display and the other as a source of parts.

Certain parts, like roof panels, are otherwise well known in the official LEGO Technic world, but are available here in a color (typically red) which is not widely offered by LEGO. So, especially if you're into building vehicles and don't mind them being dressed in a red-black palette, consider purchasing this.

While still on that topic, personally I find the white-black-white stripe along the centerline of the car incredibly ugly, stupid, infantile and wholly unnecessary. I don't blame CaDA nor Bruno Jenson as they just modelled the stripe from the original car the best they could, but Ferrari who painted it there in the first place. My hands simply resisted building something that ghastly, so I converted the entire scheme to fully red by replacing two dozen or so key parts with their red LEGO equivalents, and some help from the side. And am so much happier with its full-red outfit.

But that's the point I'm trying to make: perhaps including also the parts for a fully red F488 would have been nice ― it wouldn't mean adding that many extra parts, yet the builders would have an option to avoid the awful stripe if they wanted.

The alternate future of power

Having covered all the necessary formalities about this car, it's time to consider some less obvious points as well as this set's role in the big picture.

As you are probably aware, Power Functions have been LEGO's main line of electric Technic components for quite a while, and recently they began being progressively replaced by the TC+ which introduces some completely new concepts, but doesn't keep all of the previous ones.

Technic builders' community has generally been pretty much satisfied with the Power Functions, but with a small permanent complaint about wireless remote control never making it to the portfolio (which SBrick took the advantage of, but that's another story). Here, in this set, we've got a Power Functions clone, fully interchangeable and compatible, featuring its wireless radio controller indeed.

To my mind, this shows the alternate future of what Power Functions could and should have evolved towards: a USB-chargeable lithium battery with a built-in radio receiver featuring four channels, and its corresponding controller. And to that extent I'm excited to see whether CaDA will keep on developing its own vision of PF-compatible devices, perhaps introducing other components the community asked for (like small motors, passive potentiometers, etc.), from the point where LEGO stopped and froze it. And yes, if you were wondering, it is possible to order just these electric components in a separate pack.

Should they decide to pursue that path, it may rejuvenate the Power Functions, even though not by its original creators ― and thus establish one interesting foothold for CaDA in the technicky market. Let's not forget that many devoted Technic builders still have buckets of Power Functions components lying around, which they will certainly not want to abandon yet. And with various new problems introduced by the TC+, that abandonment may actually not come for a long time.

Therefore, this here aren't just Power Functions clones, but in a certain sense, possibly a lifeline to its continued and evolving future. Let's see how the things will work out.

Face to face with the rival(s)

The harder questions to answer are ― how does this set compare to its LEGO rivals, and what does its particular sets of pros and cons mean for both sides? Let's try to dissolve the argument to several areas.

First of all, it has to be reiterated clearly that, in several respects, CaDA C61042W beats LEGO at their own game. Despite all the undoubtedly impressive features of LEGO's recent 1:8 supercars, this F488 outplays them in functionality, design, engineering and overall sophisty. Although some come close, they are not quite at that mad level. And even if they were, they would probably not feature four motors nor a lithium battery pack with radio remote control.

But just as importantly, the underlying cause is not CaDA's personnel doing a better job than LEGO. I think noone in their right mind would ever think LEGO, with all their resources, is incapable of designing such a car as this F488. And nothing would stop them from consulting Bruno Jenson or some other renowned builder anyway, had they decided to do so.

Rather, LEGO would be reluctant to launch such a car due to several limitations they simply could not avoid from their position. They would have to license it with Ferrari, because being ridiculed for launching such an obvious copy would be damaging. Then, it would have to be simplified because LEGO would need to adhere to its policy that a large majority of the target audience should be able to build it without frustration. And with all the electric components, at LEGO's rates, it would cost the amount noone would ever be ready to pay for, except for a miniscule share of fanatics LEGO cannot make a living on. It could perhaps serve as a promotional pseudo-set, but that's a dangerously slippery slope.

So, not constrained by these inherent limitations, it is only logical CaDA had "free hands" to develop a car that could turn out to outmatch LEGO's contenders. Why didn't it happen before? Mostly because the quality of LEGO clones' parts was abysmal, and they were too concerned creating $3 garbage sets rather than having a proper attempt at something much more serious.

Then these folks from CaDA came along, improved the part quality to a level not quite as high as LEGO's but good enough, and hired one of the best guns in town to come up with a stellar model. Which resulted in a great, and surprisingly affordable, set we're dealing with here. At the time of writing this, it still costs 200 € (shipping to Europe included) on

Amazon.

David and Goliath, regardless

However hard LEGO may fight against these clones, let's be frank: even if CaDA quadruples the sales of this set overnight, LEGO would not even feel it ― such is the difference in their revenues, distribution and brand power. But the point is that the clones have now shown that they do have what it takes to play a competitive game, should they put adequate efforts in it indeed.

It doesn't alleviate the fact that clones are exactly what their name says ― clones, who reap some of their success from the work done previously at LEGO, and from the fact they can get away with an "Italian Supercar" set which is quite clearly an unlicensed Ferrari. In my view, if they want to improve their standing in that department, they should not just copy, but improve the parts: they already did so with the 36-toothed gear, and have thus shown that they can do it. That would, in the fullness of time, establish them as a more of a standalone parts company trying to complement LEGO, not just outright copying it. But that's a tall order, no doubt.

But come to think of it, why would we consider it so improbable? There is a striking analogy in the automotive world: Jeremy Clarkson once remarked wisely (for a change) that China has ascended from producing bizarre quasi-tuktuks to nearly perfectly conventional cars in just a matter of a few years. If they continued at such a pace, they would be a major player in the top league very soon. Perhaps we may witness something similar in our LEGO and LEGO clone world: the Danish giant will certainly not be dethroned soon, but it may get some quite decent competition from those dismissed as underdogs not so long ago.

And in the overall picture, that's a good thing for all the involved parties. The companies that will step up from the cloning business into good standalone set and part design should get rewarded ― there is nothing saying LEGO has a prerogative monopoly on any plastic parts sticking together. That would benefit the audience as well, with more choice: regardless of the market leaders always whining in such situations about the new players hitting below the belt and dismantling the market, in the long run it always worked out fine.

Finally, it could actually benefit LEGO to get some respectable competition. Lots of its competition so far has consisted of copycats blatantly stealing anything they could, violating all possible copyrights and intellectual property laws in existence ― and these should still be fought against. But the aforementioned serious, proper competition implementing its own ideas and skills would be a different thing entirely. LEGO themselves have become a bit overconfident with their decisions recently, and having someone directly capitalize on the wrong ones is a useful tool to keep oneself sober. As is the case in nearly all mature, established markets ― but is still an exception in this one.

It's a long shot, but maybe this is one of the first tiles on such a path. Time will tell. And in the meantime, grab those 200 Euros you've been saving for that fancy polar jacket you will ― let's be honest ― never wear anyway, and get yourself one of these instead.

+ Top-notch design

+ Insane mechanical engineering

+ Full PF-compatible wireless lithium battery, motors and remote

+ Alternate metal joints

+ Cool packaging

+ Excellent source of building material

+ Price

• Fine tolerances of parts still slightly below LEGO's standard

• Difficult to build, requires plenty of mental focus

- Occasional errors and unclarities in the instructions

- Some inconsistencies among part colors (primarily red)

Part count: 3187

Dimensions: 54 x 25 x 13 cm

Gallery