Despite the recent trend among the posts, this site is

not strictly dedicated to Lego Technic. So finally, here we go with something slightly different ― a review of a Creator set. It's the 5893 'Offroad Power', a relatively large set consisting (in the primary model) of a pickup truck, a quad and its carrier trailer.

Creator is an interesting theme as its objective is to combine a solid mechanical functionality with pretty and realistic look. Exactly this sort of combination is where this set excels at: like all great machinery in the real world, it's both great to use and to look at (and in this case, to build). Its size is respectable too, boasting over a thousand parts in a span of almost half a meter. To be precise, there's 1061 parts in the box, but not everything is used.

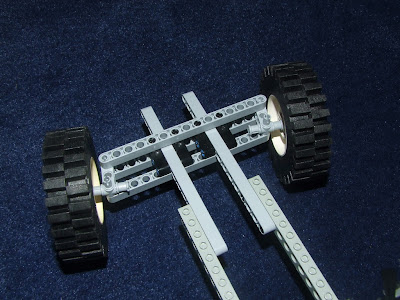

The pickup truck is the largest and the most complicated vehicle on board, but then, it has the most to offer too. It combines independent suspension with springs on the rear wheels with the freely swinging steering axle at the front, allowing the chassis to move (absorb) both vertically and sideways. The truck is easily steered with a gear on the roof and is very stable to drive. There's more: it has a functional hook-winch (a special brick for the purpose) placed in the center of the chassis, operable by easily pushing the front radiator grille via an extremely clever and subtle sliding frame. It features an automatic locking mechanism under the openable bonnet, where one can find a nicely modeled engine, too. A fantastic demonstration of efficient space and part usage! Both doors open on a hinge, the tailgate can too, and even the wing mirrors' angle is adjustable.

But, listing the technical functions, I'm doing unjustice to the overall design which deserves just as high marks. Namely, this must be one of the nicest vehicles in the arsenal: its proportions are nicely judged to match the real real trucks and there are tons of attention put into every visible surface ― slightly angled bonnet edges, headlight orientation, doors with inner compartments, a flashlight in the cabin... One can find such precise little details everywhere around the truck.

The quad follows the strong guidelines set by the truck, altohugh ― by the limitation of its size ― it cannot possibly offer much more functions than it does already: steering combined with independently freely swinging front and back main axles. However, exactly that independence makes it seriously agile if one really tries to ride it on some bumpy surfaces. It's nicely designed too, with cute details like exhausts, footrests, etc., and also fits the truck in overall scale.

Finally, it can be parked on its trailer with a retractable ramp, and let stand by itself on an extendable front mini-wheel, or attach it to the truck through a ball-joint. The trailer is very simple and is not packed with functions, but then, neither are the real-life quad-carrying trailers, are they? Thanks to the inclined "seats" for the front quad wheels to sit into, it stays nicely in place during transportation ― if it's not too steep.

It's nicely done, but let me once again stress the general point: there's rarely a set that combines as much clever and rich functionality with strong construction and high level of designer detail, as does this one.

▪ BUILDING, IDEAS AND CONCEPTS

The set (as well as the alternate models) is not too difficult to build ― most of the time it's simply from the bottom upwards, relying on the studs, though it takes time to fiddle with all the details and tiny parts if you want to make it perfect. But it's really much fun, and there's a lot to learn from it too: a subtle sliding winch-operating frame, advantages of a combined spring-loaded and free-swinging suspension, ultra-efficient usage of space and bricks, especially the hinges that the model uses abundantly. Great role model for the realistic medium scale car builders!

▪ PARTS SUPPLY

5893 is a goldmine of bricks! There are some valuable special parts, such as the automatic push-operated winch, but much more, this set is a great source of standard building material: bricks, beams, inclines, joints, plates, curves, etc., and plenty of other generally useful parts. There is a small amount of Technic too ― including the rare white studded beams. It's mostly in monochromatic and blue colours, though there are some other colours in lesser amounts as well. And it is a massive source of wheels: four large and four medium-size offroad versions, and two sportscar wheels. (And a tiny one for the trailer, if we'll be so precise.)

▪ EXPANSIONS

As the truck's chassis is by far sturdy enough to withstand extra force, I reckon it could be nicely upgraded using the available space in the back. A radio listening station, perhaps? Or a mobile water desalinizer? Of course, as the truck has a ball-joint for a trailer, it's ready to accept all kinds of specialized trailers. However, as the interior is very tightly packed with parts, I suspect there is not much room for changes, at least not simple ones.

▪ OPERATION & PLAY VALUE

As said before, controls are easily accessible, and its really great to play too, with its many moving parts and construction that will drive smoothly over all kinds of surfaces. And even when not in use, its refined looks make it valuable as a display model as well.

▪ GENERAL PROS & CONS

+ Well-judged proportions and very detailed design

+ Plenty of moving parts and functionality

+ Not too difficult to build, nice to play

+ Good role model for efficient and nice construction

+ A massive goldmine of building material

- Somewhat pricey (but then, you do get what you've paid for)

- Takes much patience to build small details uniformly and perfectly

▪▪ VERDICT ▪▪

5893 is an excellent set ― great to build, play and learn from, and is a heavy source of parts. While some very dedicated Technicians could probably stuff more functionality within the constraints, it would never have such looks and intricate details. So, a nice compromise between "pretty" and "technical" sets, taking many important points from both and combining them into a tightly packed, cleverly designed model. Two thumbs up!