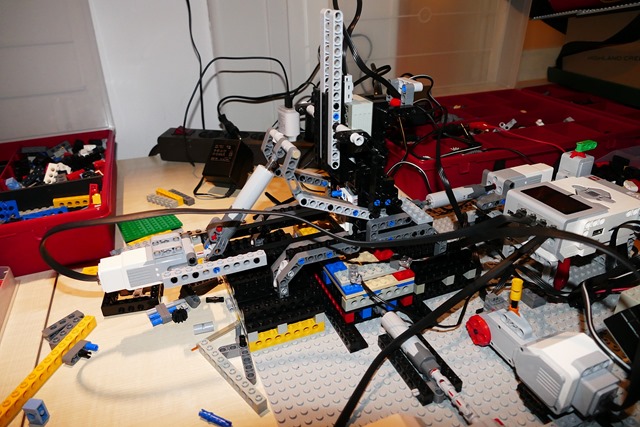

Yes, it has already gone as far as the fourth iteration; I'm still convinced that the "proper" 3D CNC cannot be done using this design for a variety of reasons I've touched on in the earlier posts, but at least the engraving part seems to be more or less satisfactory now. I've experimented with about a dozen possible improvements, among which some made it to the final version (that is, final for this fourth one at least).

The one that made the largest difference was possibly the conversion from pure "vertical" rack mechanism that raises and lowers the drill into one based on parallelogram linkage. This means that the vertical movement of the drilling head is circular rather than perfectly vertical and linear, but if adjusted properly, it does not cause any problems, while it simplifies the mechanism a lot and also makes it more precise and sturdy.

The one that made the largest difference was possibly the conversion from pure "vertical" rack mechanism that raises and lowers the drill into one based on parallelogram linkage. This means that the vertical movement of the drilling head is circular rather than perfectly vertical and linear, but if adjusted properly, it does not cause any problems, while it simplifies the mechanism a lot and also makes it more precise and sturdy.

The first design's parallelogram was controlled by a linear actuator fixed to a point on the drilling head itself. Although very practical and elegant, this had an unwanted side effect: the entire construction was strained which led to bending and therefore, inaccurate drilling points. Therefore the linear actuator was moved onto the "sledge", reducing the effect to a negligible level. This also offset the center of gravity of the sledge, but this turned out not to cause any problems, it seems even to have actually made the entire structure more stable.

Drill bit is now held by a structure that forces two rubber 2L connectors one next to the other, as the drill itself is squeezed right in between. Though I've got to admit being somewhat skeptical about this solution at first, it actually turned out to keep the drill bit nicely and reliably centered. And has the advantage of allowing nearly any sort of drill bit being used, at least as long as they are not overly thick, that is, over a few millimeters.

Drill bit is now held by a structure that forces two rubber 2L connectors one next to the other, as the drill itself is squeezed right in between. Though I've got to admit being somewhat skeptical about this solution at first, it actually turned out to keep the drill bit nicely and reliably centered. And has the advantage of allowing nearly any sort of drill bit being used, at least as long as they are not overly thick, that is, over a few millimeters.

In order to conserve power and the classic 9V motor used to rotate the drill bit (without any gearing), it is run only when needed, i.e. during drilling, and turned off while moving the drilling head about. This is done indirectly, using a fourth EV3 motor which flicks the Power Functions switch directly through an axle. This also, after a few adjustments, turned out very reliable, and was dismantled only when I accidentally manually rotated the motor too much.

The results have altogether been pretty good - the engraved images are noticeably clearer and more precise than its predecessors. The critical parameter is the force by which the drill point pushes against the engraved surface, and this is something that needs to be accurately set manually. I suppose this could in theory be done by using contact sensors, but it would - because of very little distances involved - ask for a complete overhaul of the design. That might perhaps turn out to be the mission objective for the future Mark 5, should it ever turn out to see the light of day.

The results have altogether been pretty good - the engraved images are noticeably clearer and more precise than its predecessors. The critical parameter is the force by which the drill point pushes against the engraved surface, and this is something that needs to be accurately set manually. I suppose this could in theory be done by using contact sensors, but it would - because of very little distances involved - ask for a complete overhaul of the design. That might perhaps turn out to be the mission objective for the future Mark 5, should it ever turn out to see the light of day.

Finally, instead of controlling everything from the computer, now the engraver itself offers a green and a red button, the red one to terminate the process at any time, and the green one to firstly confirm the engraving area (the drill point makes a run around the to-be-drilled area to ensure there are no obstructions), and later to pause the drilling process.

The maximum engraved image size is still limited by the extents of the linear actuators, which turns out to about 5-6 centimeters in practice. This is more than enough for cutlery or bricks, of course. Shifting the approach over to the new linear racks could increase it to at least 8-9 centimeters square, but would require more compensating movements because of the backlash between racks and pinions and therefore perhaps reduce the accuracy a bit. I've written already elsewhere, and I still think, that a longer linear actuator or actually a linear rack as envisioned by MinuteBot would help a lot - if only it was viable for its makers.

The maximum engraved image size is still limited by the extents of the linear actuators, which turns out to about 5-6 centimeters in practice. This is more than enough for cutlery or bricks, of course. Shifting the approach over to the new linear racks could increase it to at least 8-9 centimeters square, but would require more compensating movements because of the backlash between racks and pinions and therefore perhaps reduce the accuracy a bit. I've written already elsewhere, and I still think, that a longer linear actuator or actually a linear rack as envisioned by MinuteBot would help a lot - if only it was viable for its makers.

Another thing this design has improved upon is reproducibility. Since it relies mostly on common parts and is a very barebone approach, it is rather easy to rebuild it on demand quickly and painlessly. Anyway, nearly all X-Y-Z control mechanisms tend to converge to similar designs after all, given the same premises. As a pure challenge I've thought of building it as an alpha-beta-Z mechanism, i.e. involving two rotors rather than X-Y axes, but I don't see any particular advantage over the existing design, except for perhaps looking better.